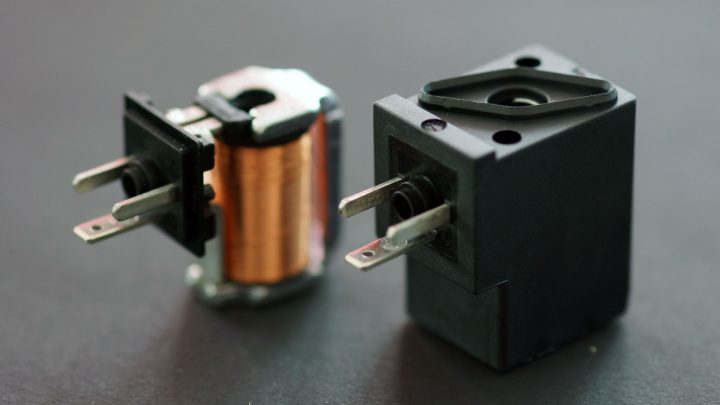

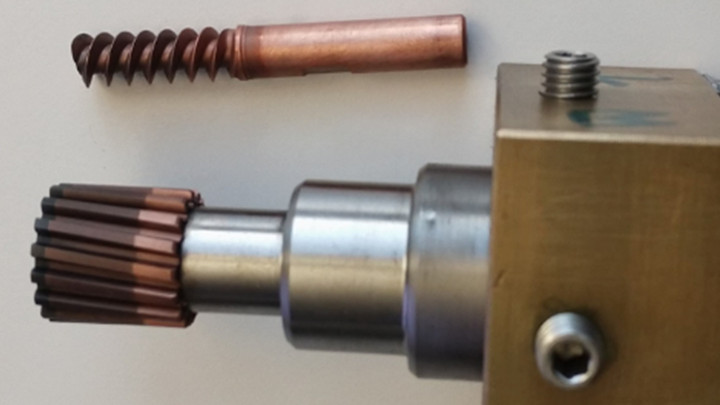

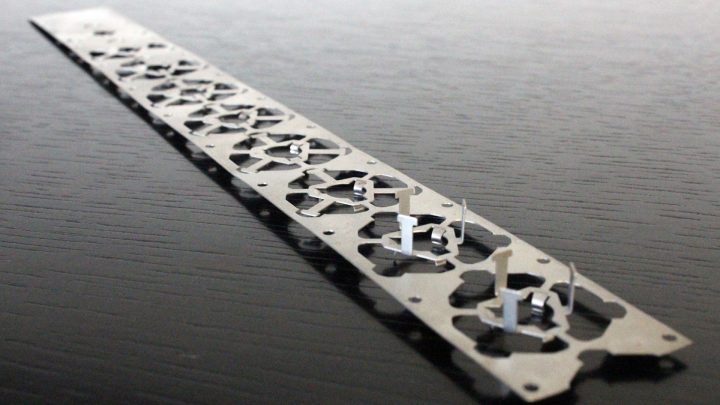

Single Components

We develop and manufacture injection molds with clamping forces of up to 400 tons for various different materials. Mold dimensions of up to one cubic meter can be processed in our own production facilities. Our portfolio includes cavity numbers from 1 through 192.

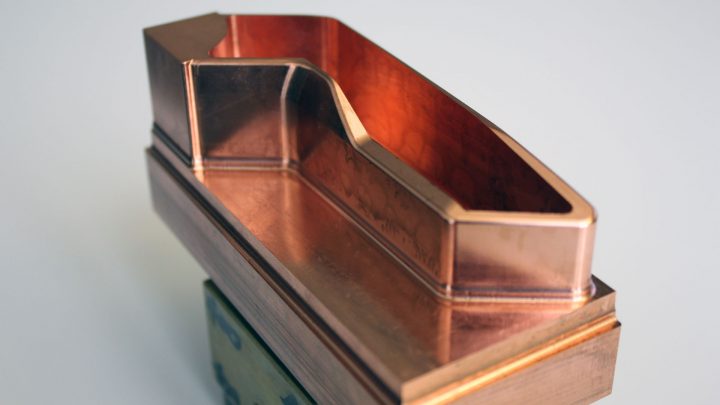

Juice Cap (Packaging)

Cycle time and a high number of cavities are of primary importance. Our solutions for these are hot-runner molds with close contour cooling systems and maximum repetitive accuracy.

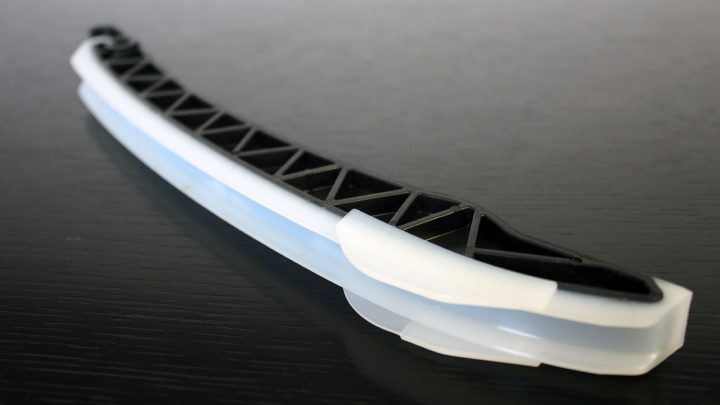

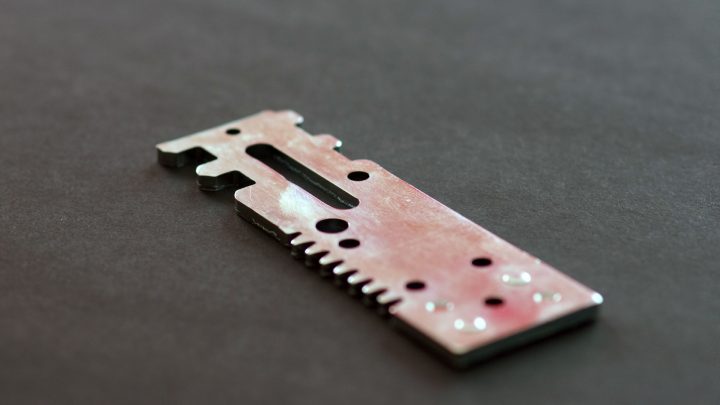

Flange (Automotive)

Technical materials and complex demolding processes are both challenges that we enjoy tackling.