Swissness

«Our location is an advantage.

At least that’s what our clients say.»

Solutions for tricky, challenging projects are what we do well.

Distance isn’t important? Our customers see things differently: Our location in the center of Switzerland – and in the center of Europe – is one of the reasons why they decide to work together with us. The development of a mold, as well as its operation and support requires close cooperation. Lucky that we’re close by: Relatively short distances, a common language and face-to-face meetings increase efficiency and build trust.

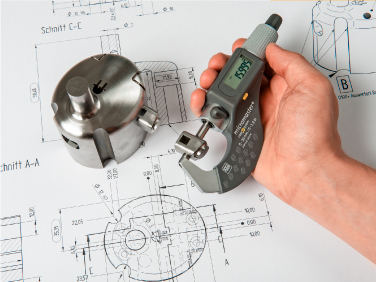

Swiss Quality, Without Compromises

Many of our products are in use for several years with only low maintenance requirements. Our injection molds guarantee consistent workmanship, from the first to the last cavity. The same quality standards apply in the medical and food areas: Our injection molds comply with the most stringent requirements for production in a cleanroom environment. Just typically Swiss.

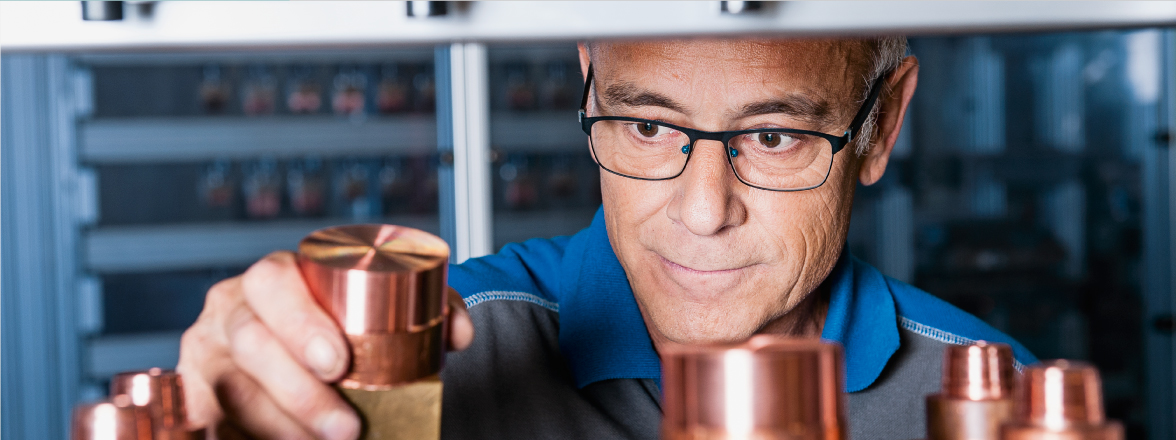

We provide our own competent new talent: We train polymechanics and engineers in our plant. Many of them then remain as qualified professionals in our company. Requirements are high: Performance and expertise are as important as willingness to take on responsibility – for persons, machines and processes.