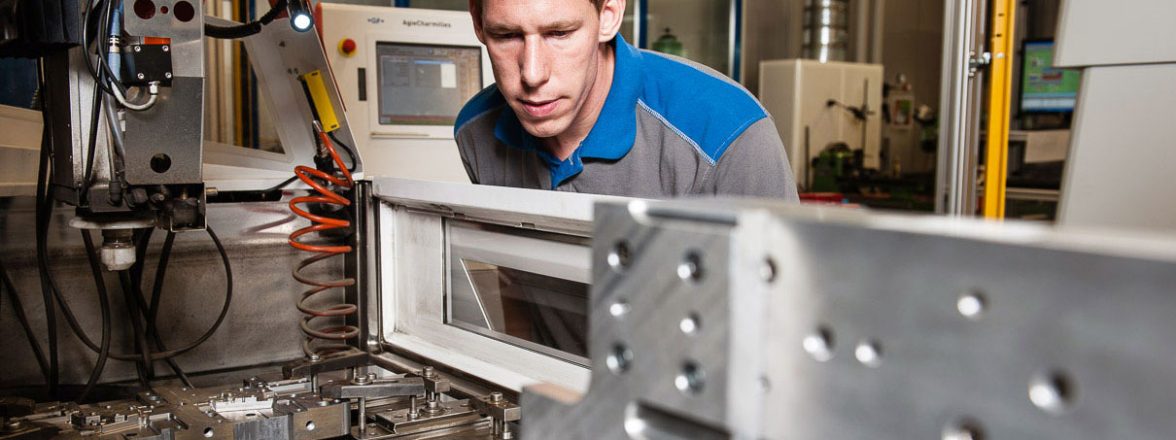

Development

We offer everything from one source, from the initial concept for a plastic-suited part geometry up to the definitive mold design.

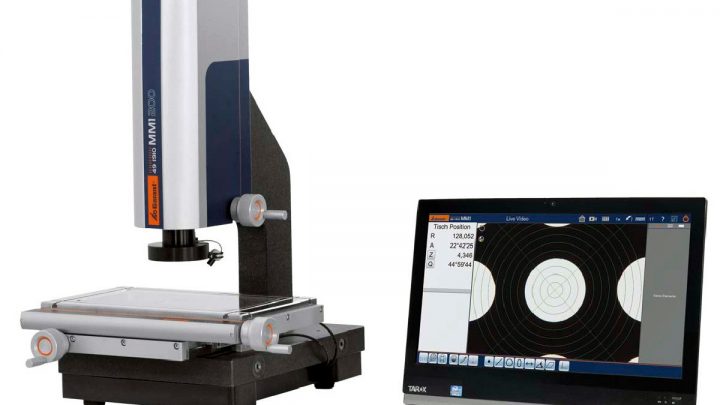

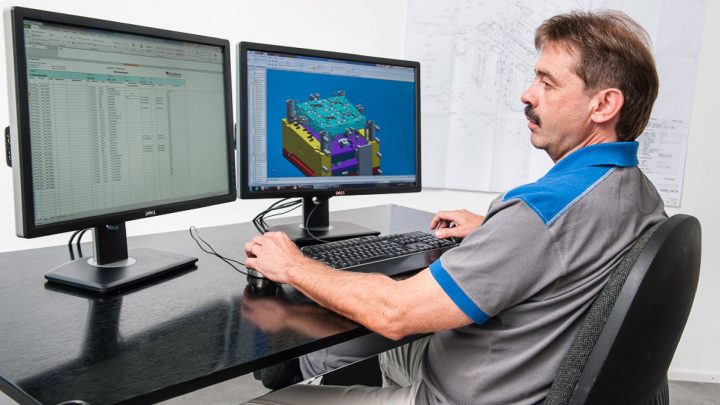

Consulting And Project Planning

We will support you in your choice of the correct manufacturing process, in the development of the perfect mold concept and in the definition of the necessary facilities.

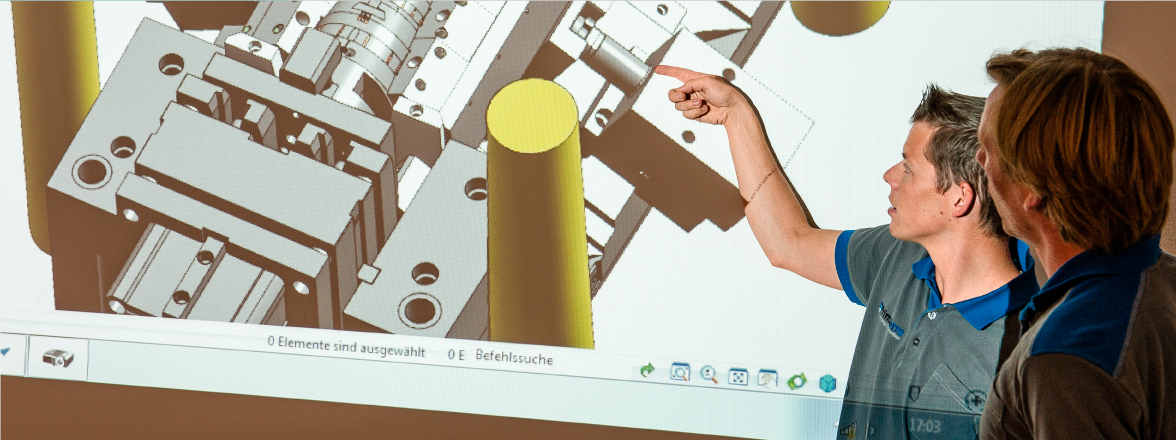

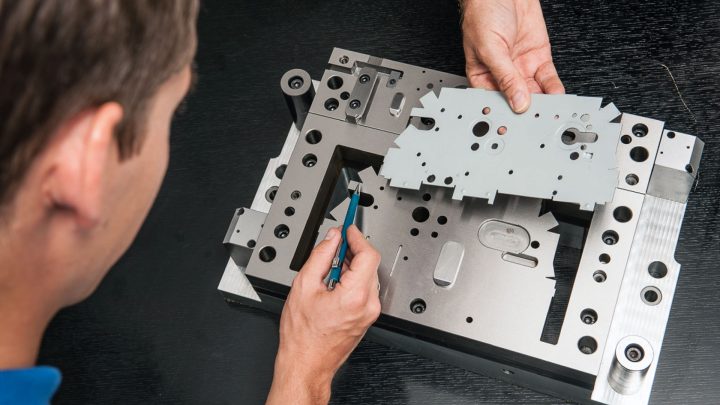

Design

Thanks to our in house engineering, we are able to work together directly, are in close contact with production and can thus find the best solutions.

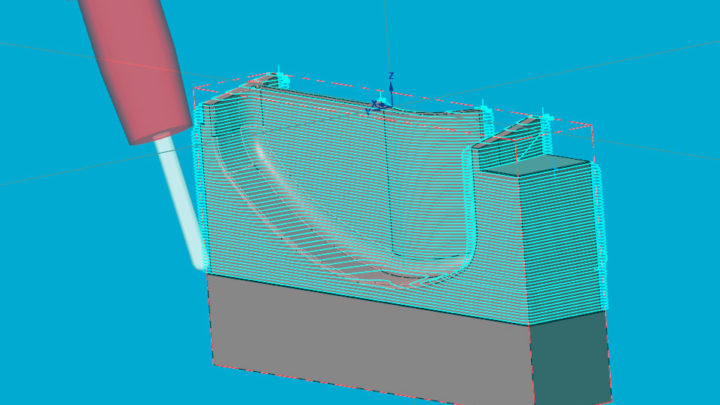

Programming

All programs are created from the 3D model. The respective strategies, technologies and programs are sent directly to the machines. This can reduce the lead time and minimize the risk of errors.